Customized Service Solutions

EcoGuardian™ Ballast Water System

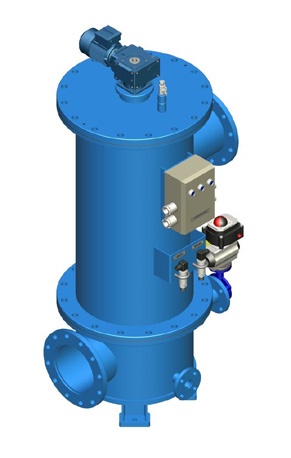

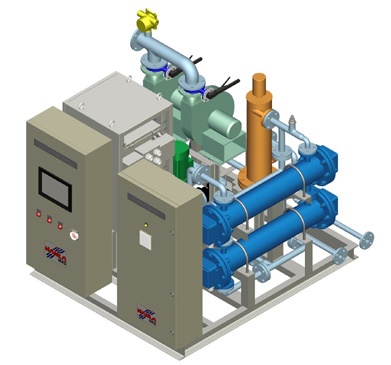

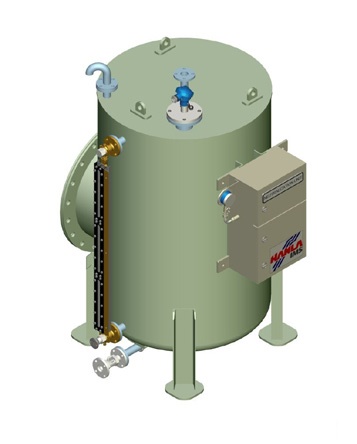

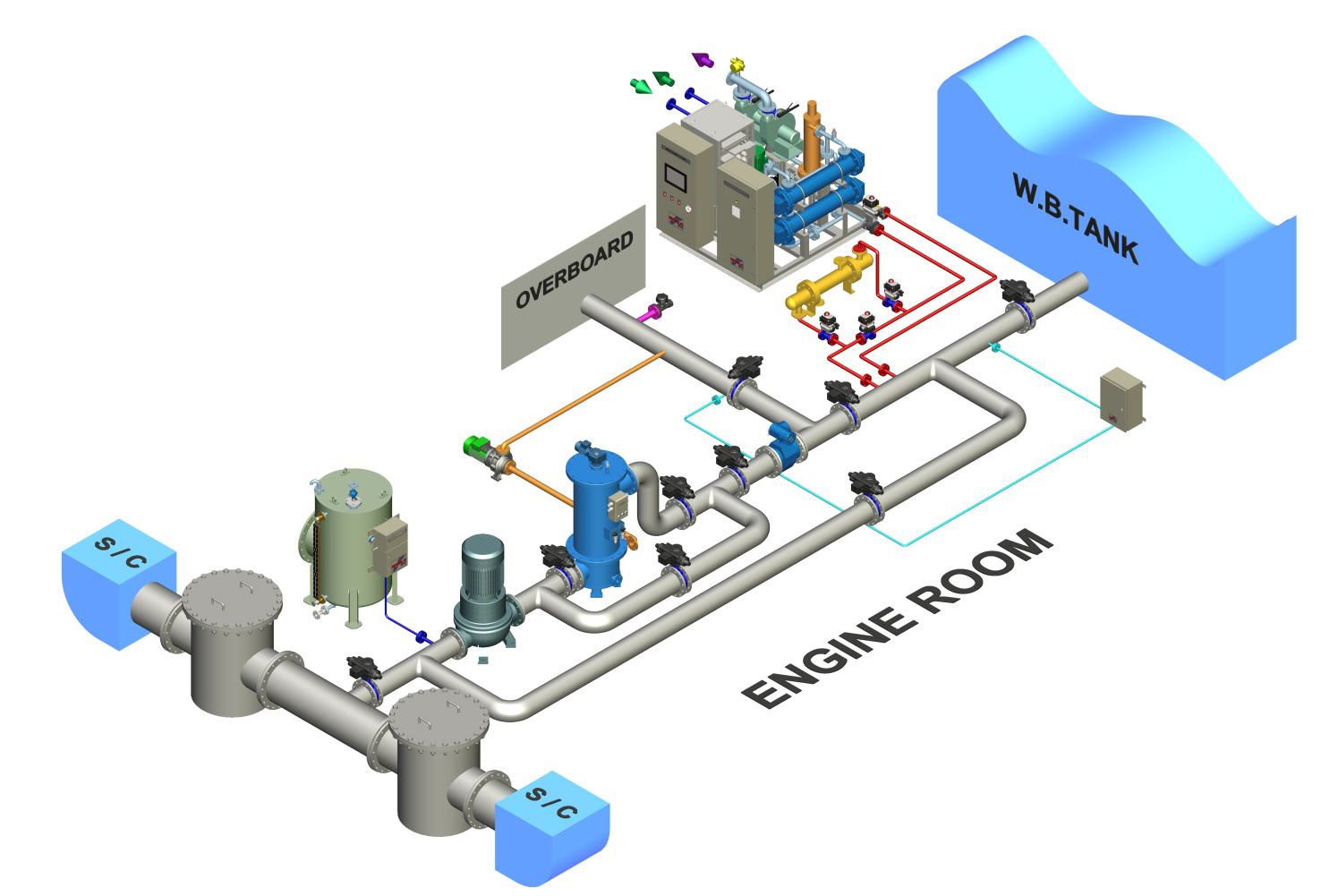

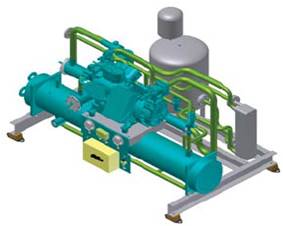

The EcoGuardian™ system from Hanla IMS uses the side-stream type treatment technology of filtration + electrolysis to treat ballast water. The system can be installed skid mounted (shown), containerized or separately. As the Hanla agent for the Americas, please contact STX Service Americas with any questions or plans you might have.

Current Approvals

Approvals in Progress

Lube Oil Solutions

Proper Lube Oil Filtration has proven to be the key factor in reducing the component wear while increasing the oil and life cycle to provide a clean, low maintenance and environmentally friendly solution for the engine. The Centrifugal Filter requires a supply of pressurized oil and in majority of applications the oil supply is obtained at engine pressure through the lube oil pump. Incase of insufficient oil pressure the pump capacity can be exchanged. In addition, we recommend the filter to be mounted at a 10 degree angle. This helps the oil leaving the centrifugal filter to fall back to the engine's oil sump under gravity.

MGO Chiller Unit

The fuel system consist of normal heavy fuel oil tank and an MDO/MGO fuel oil tank for operation in restricted areas and on some systems equipped with a fuel switch from HFO to MDO/MGO. Viscosity on the engine can be influenced by many factors such as engine condition and maintenance. fuel pump, engine adjustment, fuel temperature in the fuel system, and human factors. The MDO/MGO cooling can be installed after the circulating pumps as shown in the diagram. The advantage of installing the cooler just before the engine/generator is to optimize the viscosity regulation at the engine/generator inlet.

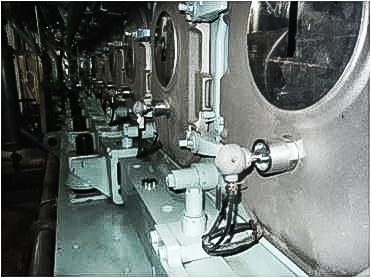

Splash Oil Monitoring System

The Splash Oil Monitoring System immediately shuts down the engine even at the slightest increase in crank-case oil temperature to prevent major engine damages.